WD-J series microcomputer controlled special testing machin

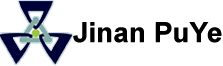

Product name: WD-J series microcomputer controlled special testing machine for scaffold couplers

Product introduction

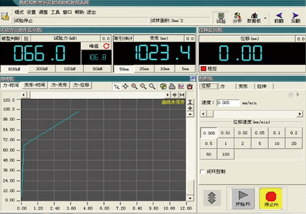

1) Modular unit: Various accessories are flexibly interchanged, and modular electrical hardware is convenient for function extension and maintenance;Product introduction

The microcomputer controlled special testing machine for scaffold couplers is designed according to the test methods of GB/T15831-2006 Steel Tube Scaffold Couplers and GB/T24911-2006 Bowl-Coupler Type Steel Tube Scaffolding Member. It can satisfy anti-slide performance tests and damage resistance tests of right-angle couplers and rotary buckles, torsion rigidity performance tests of right-angle couplers, tensile performance tests of butt couplers and compression resistance tests of base.

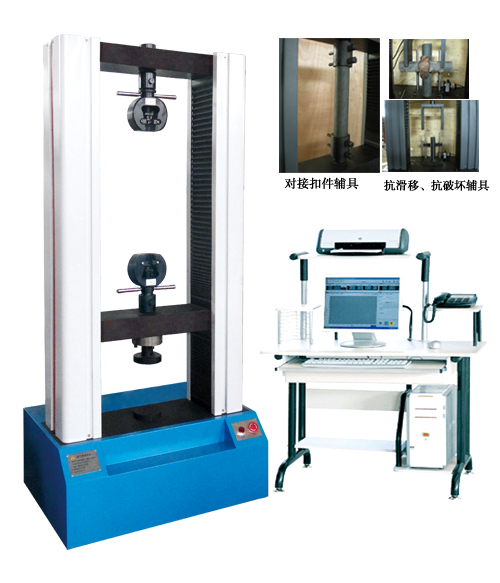

This machine adopts a computer for control, acquisition, analysis and processing of test data, drawing of stress-strain, force-time, stress-displacement curves, and it can print test reports; this machine adopts the latest control technology, and through AC digital controller, it controls the servo motor to drive the reducer and enables two pairs of high-precision screw rods to move the testing bench, and the testing bench can run at the speed of 0.005~200mm/min. When the high-precision spoke-type sensor is used on the force measuring source, its precision can reach 1%, with high sensitivity, and the whole system can reach the precision of Grade 1; it is equipped with a commercial computer of leading brand as controlling machine, for setting of test parameters, controlling of working condition, data collection, processing and analysis, display and printing of test results; the measuring control system is configured with the SMART TEST control system.

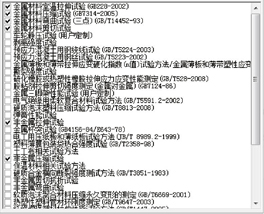

WD-J series electronic tensile testing machine is manufactured in accordance with the national standard GB/T16491-2008 Electronic Universal Testing Machines, and the product quality fully satisfies the requirements of national standards, such as GB/T12160-2002, GB/T16825-1997, GB/T228.1-2010, GB/T15831-2006 Steel Tube Scaffold Couplers and GB/T24911-2006 Bowl-Coupler Type Steel Tube Scaffolding Member.

Functional characteristics

1. The user interface supports Win7, real-time curve display, statement and curve processing, curve visualization, software structure modularization, data storage and processing based on MS-ACCESS database, being convenient for connection with OFFICE and office software.

Functional characteristics

1. The user interface supports Win7, real-time curve display, statement and curve processing, curve visualization, software structure modularization, data storage and processing based on MS-ACCESS database, being convenient for connection with OFFICE and office software.

2. It has powerful test management functions, and the test unit can be randomly set according to demands.

3. Corresponding test programs may be added according to the requirements of different users’ standards, and as long as corresponding test programs are selected upon tests, you can complete tests according to the requirements of standards and output the test reports meeting the requirements of standards.

4. Test process and equipment status real-time display, such as equipment operating status, program control operating step, and prompt of switching completion of extensometer.

3. Corresponding test programs may be added according to the requirements of different users’ standards, and as long as corresponding test programs are selected upon tests, you can complete tests according to the requirements of standards and output the test reports meeting the requirements of standards.

4. Test process and equipment status real-time display, such as equipment operating status, program control operating step, and prompt of switching completion of extensometer.

5. Powerful curve analysis function

You can select various curves, such as load-deformation and load-time curves, and select the real-time display of one or more curves. The curves of samples of the same group may be made in different colors and superposed and compared with each other, and the curves can be traversed; any section of test curves can be partially enlarged for analysis, and it supports display and marking of various feature points on the test curves; it also supports automatically or manually taking points from the curves for comparative analysis, and the curves marked with feature points can be printed and output in the test reports.

You can select various curves, such as load-deformation and load-time curves, and select the real-time display of one or more curves. The curves of samples of the same group may be made in different colors and superposed and compared with each other, and the curves can be traversed; any section of test curves can be partially enlarged for analysis, and it supports display and marking of various feature points on the test curves; it also supports automatically or manually taking points from the curves for comparative analysis, and the curves marked with feature points can be printed and output in the test reports.

6. The Smarttest software supports setting of automatic judgment, and after specimens yield, it will switch deformation to displacement collection, and it will remind users of “deformation switching finishes, and the extensometer can be removed” on the operation interface.

7. Automatic return: The movable beam can automatically return to the initial position upon tests.

8. Automatic calibration: Load and extension can be automatically calibrated according to the standard value added.

9. Mode of measurement range: The whole measurement range is not graded.

7. Automatic return: The movable beam can automatically return to the initial position upon tests.

8. Automatic calibration: Load and extension can be automatically calibrated according to the standard value added.

9. Mode of measurement range: The whole measurement range is not graded.

2) Automatic switching: The display curve can automatically change the measurement range according to the test force and deformation during test.

Technical parameters

| Name | WD-J4 series | WD-J6 series |

| Maximum test force | 100kN | 200kN |

| Effective force measurement range | 0.4%-100% of the maximum test force | |

| Force measurement accuracy and resolution |

Within ±1% of the indication 1/500000 of resolution of force value |

|

| Deformation measurement accuracy | Within ±1% of the indication | |

| Test speed | 0.001mm/min~500mm/min stepless speed regulating | |

| Speed accuracy | Within ±1% of the indication | |

| Maximum tensile distance | 600mm | |

| Effective width | 510mm | 550mm |

| Measurement accuracy of displacement | Within ±1% of the indication | |

| Power of power supply | 220V, 2kW | |

| Boundary dimension | 920×700×1850mm | 1040×610×2450mm |

| Weight | 450kg | 800kg |

上一篇:没有了

下一篇:没有了