GW-50B steel bar bending test machine

Product introduction

GW-50B type steel bar bending test machine is Bending test machine is a test equipment for flat and reverse bending test of steel bars. The main technical parameters and indicators of the equipment are in accordance with GB/T1499.2-2018 (instead of GB/T1499.2-2007) Steel for reinforced concrete - Part 2: Hot rolled ribbed bars, GB/T28900-2012 < Steel test method for reinforced concrete>, YB/T5126-2003< reinforcement in reinforced concrete bending and reverse bending test method > (instead of GB5029-85< steel plane reverse bending test method >),The requirements of test equipment for steel mills and the construction unit test of rebar bending strength not less, also applies to steel construction industry to be bent in the field test and construction of a dual-purpose machine of.

GW-50B type is GW-2/25 type and GW-2/40 type alternative products, through the replacement of different specifications of the machine parts can replace two machine, saving money for the equipment customers. The equipment has complete performance, good quality, compact structure, small size, easy operation, easy to control the bending angle, simple and stable operation, low noise, long life, reliable design, convenient maintenance and easy lubrication. The limit of the device is changed to a mechanical limit switch, which is more convenient and durable to use, the design of the wearing parts is more reasonable, and the cutting edge of the wearing part is easy to replace. In addition, the device also adds the alarm function of the photoelectric switch abnormal controller, which avoids the problem that the system is not stopped due to the problem of the signal collected by the proximity switch.

Technical Parameters

| project | technical index |

| Bar bending diameter range (three grade rebar) | Φ6-Φ50mm |

| The forward bending angle of the reinforcing bar | 0°~180°arbitrarily set |

| The bending angle of the reinforced bar | 0°~90°arbitrarily set |

| Working speed | ≤1.4r/min |

| Roller center distance | 280mm |

| The work plate whose diameter | Φ860mm |

| Motor power | 3.0kw |

|

Randomly equipped with a curved core set (mm) HRB500 HRBF500 Can complete the bending performance test of steel bars (180°) |

6×Ф6、6×Ф8、6×Ф10、6×Ф12、6×Ф14、 6×Ф16、6×Ф18、6×Ф20、6×Ф22、6×Ф25、 7×Ф28、7×Ф32、7×Ф36、7×Ф40、8×Φ50 A total of fifteen |

|

HRB400 HRBF400 Order separately Can complete the bending performance test of steel bars (180°) |

4×Ф6、4×Ф8、4×Ф10、4×Ф12、4×Ф14、 4×Ф16、4×Ф18、4×Ф20、4×Ф22、4×Ф25、 5×Ф28、5×Ф32、5×Ф36、5×Ф40、6×Φ50 A total of fifteen |

|

HRB600 HRBF600 Order separately Can complete the bending performance test of steel bars (180°) |

6×Ф6、6×Ф8、6×Ф10、6×Ф12、6×Ф14、6×Ф16、6×Ф18、6×Ф20、6×Ф22、6×Ф25、7×Ф28、7×Ф32、7×Ф36、7×Ф40、8×Φ50 A total of fifteen |

|

HRB400E HRBF400E If the steel bar reverse bending performance test needs to be completed Order separately (positive bend 90°, reverse bend 20°) |

5×Ф6、5×Ф8、5×Ф10、5×Ф12、5×Ф14、 5×Ф16、5×Ф18、5×Ф20、5×Ф22、5×Ф25、 6×Ф28、6×Ф32、6×Ф36、6×Ф40、7×Φ50 A total of fifteen |

|

HRB500E HRBF500E If the steel bar reverse bending performance test needs to be completed Order separately (positive bend 90°, reverse bend 20°) |

7×Ф6、7×Ф8、7×Ф10、7×Ф12、7×Ф14、 7×Ф16、7×Ф18、7×Ф20、7×Ф22、7×Ф25、 8×Ф28、8×Ф32、8×Ф36、8×Ф40、9×Φ50 A total of fifteen |

| Working roll(mm) | Φ52、Φ68 each one |

| Bending mandrel(mm) | Φ56 |

| Overall size | 1350×1180×1100mm |

| Weight | 2000kg |

Operation of GB/T1499.2-2018 steel bar double-direction bending testing machine:

Before the test, turn on the power switch, set the values of forward and reverse bending angles, press “set” key and “select” key to choose forward bending or reverse bending, press “<” or “>” to select the number of bits of the cursor, and press “+” and “-” to increase or decrease figures, and finally, press “OK” key to confirm the angle, and after pressing, you can carry out bending tests on steel bar.

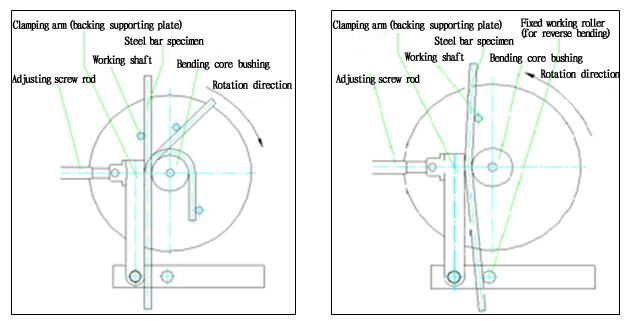

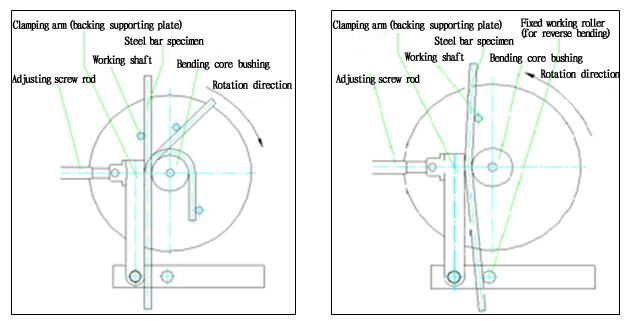

Automatic forward bending test: Mount the working shaft and bending core bushing on the working disk as shown in Figure 3, press the “inching reverse bending” key to reversely rotate the working disk to the initial position, and put steel bar to carry out the test, the clamping device will clamp the specimen firmly, and then, press the “inching forward bending” key to make the forward bending working shaft close to and contact the specimen, and then, press the “automatic forward bending” key, and the testing machine will automatically forward (clockwise) bend and continuously display the current bending angle, and when the angle reaches the set angle, the testing machine will automatically stop. Press the “zero clearing” key to prepare the next test.

Automatic reverse bending test: Put the specimen after forward bending and reverse bending working shaft as shown in Figure 4, and the clamping device will clamp the specimen firmly, and then, press the “inching reverse bending” key to make the reverse bending working shaft close to and contact the specimen, and make the other end of specimen close to and contact the reverse bending barrier shaft, and then, press the “automatic reverse bending” key, when the testing machine will automatically reverse (anticlockwise) bend and continuously display the current reverse bending angle, and when the angle reaches the set reverse bending angle, the testing machine will automatically stop. Press the “zero clearing” key to prepare the next test.

(Figure 3) Schematic Diagram of Forward Bending (Figure 4) Schematic Diagram of Reverse Bending