JB-S series Digital impact testing machine

product name:JB-S series Digital impact testing machine

Product introduction

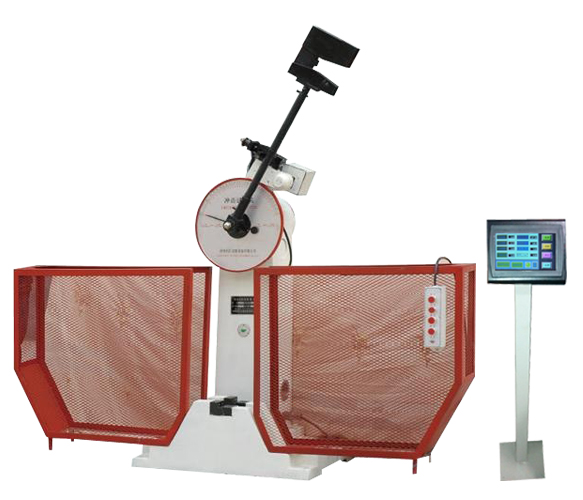

JB-S series impact testing machine for determination of metal materials under dynamic load, impact resistant performance, in order to determine whether the materials in dynamic load properties. The testing machine according to the national standard GB/T3808-2002< swing hammer impact testing machine test > development and production, according to the national standard GB/T229-2007< metallic materials Charpy pendulum impact hammer test method > impact test of metallic materials, the cross-section of the sample has a larger impact energy for 10 x 10 mm; testing machine, so mainly for impact toughness test larger black metal, such as steel and alloy

Product details

The use of JB-S type impact pendulum impact before the potential energy and impact testing machine after the remaining potential difference displayed in the dial on the way, get the absorbed energy of the sample; PLC controller is used to control the test process, simple operation, high work efficiency, in the thrust specimen by residual energy is automatically measured by Yang pendulum sensor thrust angle swing hammer anti Yang specimen, automatic digital display (LCD) anti yang angle value and the pendulum made to sample power AK value. The optional micro printer can print test data, including: the value of AK, the impact toughness of the AK value, the three sample average power (AK/3) and time the number of content. For a large number of impact tests of metallurgy, machinery manufacturing factory, pressure vessel factory. Note: the micro printer configuration option, the price is another.

Main features

◆Significant advantages of software and operating systems

1. 7 inch touch screen controller and dial at the same time display, data synchronization, equipped with a dual display system, do not interfere with each other, flexible operation, high efficiency.

2. can be continuous hundreds of specimens of continuous testing, manual operation just as by placing the specimen and press the action button, all the rest of the work is testing machine automatic completion, reduce labor intensity, the complete elimination of artificial data recording error probability, is particularly suitable to be used in a large number of samples of metallurgical mining industry.

3. optional special features rich pendulum impact test software, intelligent, menu based operation, take place, return pin, impact, put the pendulum and other test operations can be done on the touch screen controller to click on the way.

◆Significant advantages of electrical control section

1. to import the PLC controller as the core of the electrical control system, using high precision photoelectric encoder as the angle acquisition sensor.

2. integrated circuit board, maintenance is more simple.

3. using the brush clutch to replace the old clutch, the test, the pendulum automatic take place, the clutch is effectively protected, reduce the system to the clutch tooth damage, prolong the system life.

◆Significant advantages of security

Use of high toughness materials semi closed door cover contains the pendulum the orbit, and also prevent being washed off the sample spatter wounding, maximize avoid misoperation brought to the operating personnel injury, ensure safety.

| impact energy | 300J | 500J |

|

Impact energy range |

0-150J/0-300J | 0-250J/0-500J |

|

angular resolution

|

≤0.1° | ≤0.1° |

|

Index value of each small grid

|

1J/2J | 2.5J/5J |

|

Pendulum force (impact constant)

|

0—150J 0—300J M=80.3848N.m M=160.7695N.m |

0—250J 0—500J M=133.9746N.m M=267.9492N.m |

|

Swing hammer angle

|

150° | 150° |

|

The pendulum shaft rotation center to the point of impact

(sample center) distance

|

750mm | 800mm |

| impact speed | 5.2m/s | 5.4m/s |

|

The sample bearing span |

40mm | 40mm |

| Jaw fillet | R1—1.5mm | R1—1.5mm |

| Impact edge fillet | R2—2.5mm | R2—2.5mm |

| Sample size | 55×10(7.5/5)×10mm | 55×10(7.5/5)×10mm |

| Testing machine net weigh | 450kg | 550kg |

| Testing machine dimensions | 2124×600×1340mm | 2300×600×1400mm |

| current source | three-phase four-wire system 50Hz、380V、180W(Main motor) | |

| S/W series angle resolution | ≤0.03° | |

| S/W series A/D conversion | 24 bits | |

| S/W series sampling rate | ≤20ms | |