WD-P6-II series electronic universal testing machine

Microcomputer control electronic universal testing machine can be of metal, non-metallic materials and composites of mechanics performance test and analysis, which can make a variety of insulating materials tensile, compression, bending, the detection of tearing, cutting, stripping and other projects. Widely used in aerospace, petrochemical, machinery manufacturing, vehicle manufacturing, wire and cable, textile fibers, plastics and rubber, ceramic building materials, food, pharmaceutical packaging, metal materials and products industry

Product detailsThis machine adopts computer control, acquisition, analysis and process the test data, draw should stress - strain, force time, force - displacement curve, and print the test report; the machine using the new control technology, through the exchange of digital controller, control servo motor drives a reducer, take the two subtropical high precision leadscrew moving testing table.。In the measurement of high precision wheel spoke type sensor used in the power source, the precision can reach 1%, the high sensitivity, the whole system to achieve level 1 accuracy; equipped with mainstream brand commercial computer as the control unit, the setting of test parameters, working state control, data acquisition, processing and analysis, display and print the test results; in the measurement and control system is configured smart test control system.

functional characteristics

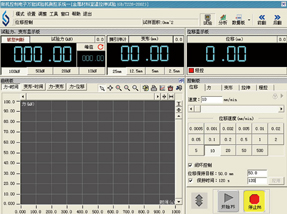

1. User interface supports win7, real-time curve display, report, curve processing, image curve and modular software structure, data storage and processing based on MS-Access database for the office and other office software connected.

2. With a strong test management function, the test unit can be arbitrarily set according to demand.

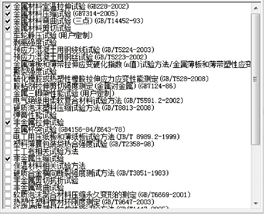

3. You can add the appropriate test program according to the standard requirements of different users, test as long as the choice of the appropriate test program can complete test according to the standard requirements and output test reports that meet the requirements of the standard.

4. Test process and equipment state of real-time display, such as the running state of the equipment, program control operation steps, extensometer switch prompts to complete the etc.

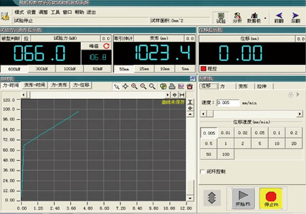

Load - deformation, load time curve, real-time display including one or more. Curves of samples in the same group can use different additive color contrast, traversing curve and test curve of arbitrary section can be magnified for analysis and support in the test curve display and labeling of each feature point, in the curve automatically or manually take some comparative analysis and mark the feature points of the curve can also print output in the test report.

6. Smarttest software can be set to automatically determine the in sample yield after deformation switch displacement collection and operation in the interface remind users "deformation switching is completed, can remove the extensometer".

7. Auto return: Mobile beam can be automatically returned to the initial position.

8. Auto calibration: load elongation can be calibrated automatically according to the standard values.

9. The range mode: full range is not classified.

1) module unit: a variety of accessories flexible, modular electrical hardware to facilitate the expansion and maintenance of function;

2) automatic switching: the test process shows the curve according to the test force and deformation of the size of the automatic conversion range.

| name | WD-P6-Ⅱseries | |

| maximum testing force | 500kN | 600kN |

| Effective measuring range | Maximum test force of 0.4%-100% | |

| Measurement accuracy and resolution |

within the ±1% of indicating value resolution of force1/500000 |

|

| The precision measurement of deformation | within the ±1% of indicating value | |

| testing speed | 0.001mm/min~200mm/min stepless speed regulating (speed ratio1:500000) | |

| speed accuracy | within the ±1% of indicating value | |

| maximum stretching distance | 700mm | |

| effective width | 660mm | |

| diameter of circular specimen(mm) | Φ4~Φ40mm | |

| thickness of flat specimen(mm) | 0~30mm | |

| displacement measurement accuracy | within the ±1% of indicating value | |

| power | AC220V±10% 6.5KW | |

| external dimensions | 1200×1050×2450mm | |

| weight | 2600kg | |