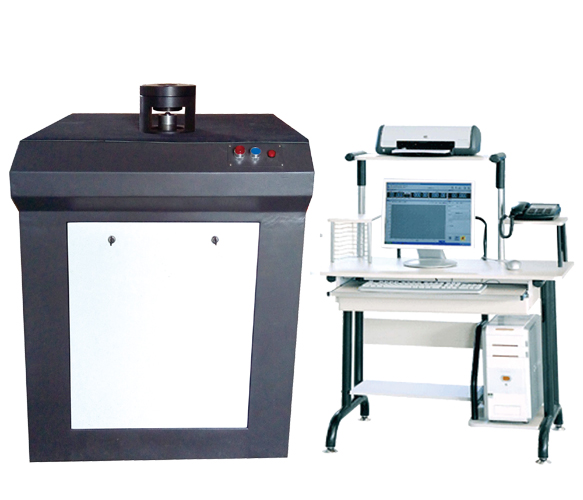

GBW-50 Microcomputer controlled cup testing machine

Product description

GBW-50 the appearance of the machine is novel, easy to meet ergonomic, it is precision equipment for metal sheet and strip for process performance testing. It can achieve GB/T4156-2007< metal materials and thin with Erickson cup test method. It can meet the requirements of 583-2010 JB/T7408-94, ASTME643-2008 standard, the plastic deformation of metal sheet and strip in the test process.

Characteristic

1. the cupping testing machine adopts the principle of the new structure, servo motor constant loading speed, can realize the constant speed control, stamping process control by computer, stamping speed can be stepless speed preset. (The last cylinder oil source afterburner cannot achieve constant rate control).

2. the clamping force is independent of the hydraulic oil source, the clamping force can be adjusted, the data synchronization display can be independently calibrated.

3. the force measuring device has been changed in the past as a hydraulic sensor spoke sensor, cupping value measurement for the encoder, punch test process with low friction mobile mobile device I pioneered, with high precision spokewise sensor (direct force) can realize the test of ultrathin sheet (0.05 ~ 3mm), and greatly improve the accuracy and reliability of test machine to measure cupping value. The perfect measurement device and loading device of the instrument and control procedures, and solves the problem of poor reproducibility of the previous experimental data, but also provides a reliable basis for the implementation of the new cupping machine verification procedure and cupping test method for our country.

4. the cup is easy to replace the mold, the sample loading and unloading is simple, the specimen is put into, the test parameters can be input, change, stamping process to achieve closed-loop control, the pressure value of the test data is easy to observe the specimen crack.

Technical parameter

| Maximum test thickness | Standard cup test 0.05~3mm(High precision sensor can realize the test of ultra thin plate) |

| maximum width of sheet | 90-100mm |

| The maximum stroke of the punch | 60mm |

| Maximum punch load |

50kNmax;(According to the pressure of t customer's material, Can be configured with maximum punch load) |

| Maximum clamping load | 10kN |

| Cup resolution | 0.01mm |

|

measurement accuracy of testing force |

±1% |

| Deformation precision | ±0.5% |

| Speed of testing | 0.05mm/min-200mm/min(stepless speed regulating) |

| Cupping test of mould specifications |

Standard punch ball:φ20±0.05mm Standard pad aperture :φ33±0.1mm Standard fixed die aperture:φ27±0.05mm |

| Computer display content |

Clamping load、Impulse pressure, displacement and cup process, rate, test curve, etc. |

| control method | Computer can achieve testing process automatically |

|

The background database uses ACCES, may according to the user request to provide many kinds of data transmission software |

|

| hydraulic fluid | NO.46 hydraulic oil (general gas station can be purchased) |

| Physical dimension | 780×780×1100(mm) |

| power | AC380V,AC220V |

| weight | 260Kg |

◆ formed punch :dpΦ32

◆ punch die:ddΦ32.28 ddΦ32.35 ddΦ32.43 ddΦ32.50

ddΦ32.60 ddΦ32.75 ddΦ32.90 ddΦ33.05

ddΦ33.20 ddΦ33.35 ddΦ33.50 ddΦ33.80

ddΦ34.10 ddΦ34.50 ddΦ35.00 ddΦ35.60

ddΦ36.30 ddΦ37.00 ddΦ38.50 ddΦ39.80