GBW-100 microcomputer controlled cupping multi-functional te

Cupping die pictures:

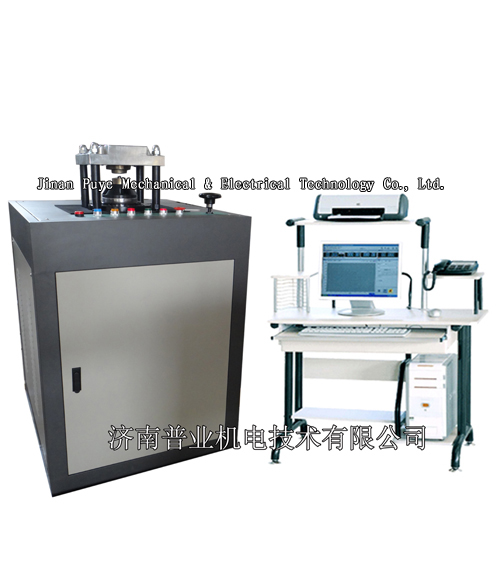

product name:GBW-100 microcomputer controlled cupping multi-functional testing machine

I. Product introduction

I. Product introduction

GBW-100 microcomputer controlled cupping multi-functional testing machine is precision equipment for technological property tests of metallic sheets and strips, and it can realize GB/T4156-2007 Metallic Materials – Sheet and Strip – Erichsen Cupping Test Method; it meets the requirements of JJG 583-2010 JB/T7408-94 and adopts the standard of ASTME643-2008; it can test plastic deformation performance of metallic sheets and strips during tests. If being added with dies, this machine can complete metallic sheet bulging, drawing, hole expansion and conical cup tests in GB/T15825.3-2008, GB/T15825.4-2008 and GB/T15825.6-2008 Sheet Metal Formability and Test Methods. This machine adopts the mechanical-electrical-hydraulic integrated design, and its appearance is neat and decent.

II. Structure principle

1. This cupping testing machine adopts a new structure principle for constant-rate loading of servo motor, and it can realize constant-rate control, and control of the stamping process by computer, and the stamping speed is stepless speed adjustable and it can be adjusted in advance. (In the past, oil source force loading of oil cylinder cannot realize constant-rate control.)

2. The clamping force is independently loaded by the hydraulic oil source, and the clamping force can be adjusted; the spoke-type sensor can directly measure force, and data can be displayed synchronously and calibrated independently.

3. The force measuring device adopts a spoke-type sensor instead of hydraulic sensor previously, and the cupping value measurement is completed by an encoder; during the test process, the plunger chip movement adopts the low-friction movement device created by our company, and combined with the high-accuracy spoke-type sensor (directly measuring force), it can realize accurate data collection, greatly improving the accuracy and reliability of cupping value measured by the testing machine. The perfect matching of the measuring device and loading device of this instrument and its control program well solves the previous problem of poor repeatability of test data, and it provides a reliable basis for our company to implement new regulations for metrological verification of cupping machines and cupping test methods.

4. It is convenient to replace cupping dies, and easy to load and unload specimens; after specimens are put in, they can be clamped when the automatic button is pressed, and the test parameters can be entered and changed, and the stamping process realizes closed-ring control; when the stamping force value declines, it will judge that a specimen has cracks, and it will automatically stop, and it is easy to observe specimen cracks at the same time. It displays test data on the computer, and has the function of peak value memory, i.e. maximum stamping force, cupping value and so on, and it can realize statement, storage, batch and curve drawing of test results, automatic memory of deformation height, and it can automatically restore to the state of waiting test after one test ends.

III. Technical parameters

III. Technical parameters

| Maximum test thickness | 0.1~4mm (high-accuracy sensor) |

| Maximum width of plate | 180mm |

| Maximum travel of plunger chip | 100mm |

| Maximum stamping load | 100kN |

| Clamping piston travel | 21-31mm |

| Maximum clamping load | 100kN |

| Resolution of cupping value | 0.01mm |

| Load accuracy | ±1% |

| Deformation accuracy | ±1% |

| Test speed | 0.05-100mm/min (stepless speed regulating) |

| Specification of cupping test die | Standard plunger ball SΦ20±0.05; standard fixed die bore diameter ф27±0.05mm |

| Computer display content | Clamping load, stamping force, displacement and cupping value, speed, test curve, etc. |

| Control mode | The computer automatically realizes the test process; the backend database adopts ACCES, and it can provide various formats of data transmission software according to the requirements of users. |

| Boundary dimension | 930mm×1260mm×1400mm |

| Power supply | 2kW/AC380V/50Hz |

| Weight | 1000Kg |

| Adopt AC speed regulating system servo motor control | The electrical design satisfies the EMC safety standard, and it has such functions as limit protection and full range overload protection. |

IV. Standard configuration

1. Specification of cupping test die:

Standard plunger ball: φ20±0.05mm

Standard cushion-type die bore diameter: φ33±0.1mm

Standard fixed die bore diameter: ф27±0.05mm

2. Parameters and specification of additional accessory die

| Bulging die of terrace die (drawing test die) GB/T15825.3-2008 (Figure No. 9000) | |||

| Terrace die | Plate thickness | Inner diameter of concave die | |

| φ50mm | 0.45-0.64mm | φ51.8mm | |

| >0.64-0.91mm | φ52.56mm | ||

| >0.91-1.3mm | φ53.64mm | ||

| >1.3-1.86mm | φ55.20mm | ||

| >1.86-2.50mm | φ57mm | ||

| Hole expansion test die GB/T15825.4-2008 (Figure No. 8100, 8200, 8300) | |||

| Plate thickness | Diameter of guide pin | Terrace die | Inner diameter of concave die |

| 0.20-1.00mm | φ5mm | φ25mm | φ27 mm |

| 1.00-2.00mm | Φ8mm | φ40mm | φ44 mm |

| 2.00-4.00mm | Φ16.5mm | φ55mm | φ63 mm |

| Conical cup test die GB/T15825.6-2008 (Figure No. 6100, 6200, 6300, 6400) | |||

| Plate thickness | Terrace die | Concave die Dd | |

| 0.5-<0.80mm | φ12.70mm | Φ14.60mm | |

| 0.8-<1.00mm | φ17.46mm | Φ19.95mm | |

| >1.00-2.00mm | φ26.99mm | Φ32.00mm | |

| >2.00-4.00mm | φ20.64mm | Φ24.40mm | |

1. Using FPGA chip, with the processing speed up to 100M, guaranteeing that no real-time data of any moment will be lost;

2. Real-time parallel data collection and processing, stable and high-efficiency control;

3. Special difference channel, the design that the power supply is fully isolated from peripheral interfaces, strong anti-jamming capability;

4. High-precision digital displacement device connected with FPGA, internal hardware counting, accurate and reliable data;

5. Double-channel 24-bit high-precision A/D collection, higher resolution and accuracy of stamping load and clamping force;

6. Microcomputer automatic control over the test process and 18.5in. liquid crystal display; the backend database adopts ACCES, and it can provide various formats data transmission software according to the requirements of users.

7. The electrical design satisfies the requirements of EMC safety standard;

8. Having such functions as limit protection and full range overload protection.

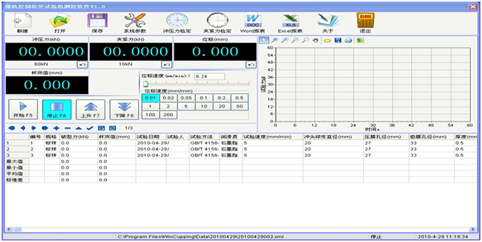

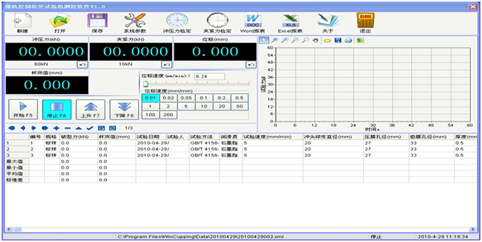

Software interface:

Software interface: