MPX-3W microcomputer controlled pin-on-disk friction and abr

Product Name: MPX-3W microcomputer controlled pin-on-disk friction and abrasion testing machine

I. Equipment introduction

MPX-3W microcomputer controlled pin-on-disk friction and abrasion testing machine is a vertical shaft pin-on-disk testing machine developed by our company based on FALEX6# multi-functional friction and abrasion testing machine, and this machine can be used for end face sliding friction tests on pin-on-disk, double-ring and ring-disk type contacting specimens made of various metallic and non-metallic materials (plastics, nylon, etc.) so as to test the wear-resisting property of various materials under selected loads and speeds and test the friction coefficient of various materials. This testing machine is a reliable testing instrument for institutes and schools to carry out teaching and scientific researches of “Tribology”.

MPX-3W testing machine is widely applied to various fields of technologies of tribology, petrochemical, machinery, energy, metallurgy, aerospace, various junior colleges and research institutes (institutions).

This machine is composed of base, rack, spindle and its AC servo drive system, friction pair disk and specimen clamping device, test force servo closed-loop applying system, electronic measurement system of all test parameters, computer and data acquisition board and card, as well as special control software. The spindle drive consists of AC servo motor and its control system, and the system can realize constant torque output within the whole range of rotation speed, and it can realize stable work at an extremely low rotation speed, realizing the stepless speed regulation of spindle within a large range and satisfying the demands of different researchers. The test force is applied automatically by the servo closed-loop system, and the magnitude can be set by operators on the computer interface, and the applying is stable and reliable, avoiding the influences of lever loading test force fluctuations on test results. The test force applying device is realized by the control of the servo system over the frictionless plunger-type cylinder pushing spring, guaranteeing accurate transmission of force value; in order to reduce the friction caused when pair disks move up and down and improve the measurement accuracy of friction (torque), linear bearings are adopted for guiding, and deep groove ball bearings are adopted for bearing. The rotation speed of spindle, the number of revolutions (test cycle), test force, friction force torque (friction coefficient, friction force), test time and other parameters of this machine are controlled by computer, and it can collect test data in real time and draw corresponding test curves, support arbitrary storage, access and printing and output, with accurate and reliable data, without influences of human factors.

II. Main technical specifications:

MPX-3W microcomputer controlled pin-on-disk friction and abrasion testing machine is a vertical shaft pin-on-disk testing machine developed by our company based on FALEX6# multi-functional friction and abrasion testing machine, and this machine can be used for end face sliding friction tests on pin-on-disk, double-ring and ring-disk type contacting specimens made of various metallic and non-metallic materials (plastics, nylon, etc.) so as to test the wear-resisting property of various materials under selected loads and speeds and test the friction coefficient of various materials. This testing machine is a reliable testing instrument for institutes and schools to carry out teaching and scientific researches of “Tribology”.

MPX-3W testing machine is widely applied to various fields of technologies of tribology, petrochemical, machinery, energy, metallurgy, aerospace, various junior colleges and research institutes (institutions).

This machine is composed of base, rack, spindle and its AC servo drive system, friction pair disk and specimen clamping device, test force servo closed-loop applying system, electronic measurement system of all test parameters, computer and data acquisition board and card, as well as special control software. The spindle drive consists of AC servo motor and its control system, and the system can realize constant torque output within the whole range of rotation speed, and it can realize stable work at an extremely low rotation speed, realizing the stepless speed regulation of spindle within a large range and satisfying the demands of different researchers. The test force is applied automatically by the servo closed-loop system, and the magnitude can be set by operators on the computer interface, and the applying is stable and reliable, avoiding the influences of lever loading test force fluctuations on test results. The test force applying device is realized by the control of the servo system over the frictionless plunger-type cylinder pushing spring, guaranteeing accurate transmission of force value; in order to reduce the friction caused when pair disks move up and down and improve the measurement accuracy of friction (torque), linear bearings are adopted for guiding, and deep groove ball bearings are adopted for bearing. The rotation speed of spindle, the number of revolutions (test cycle), test force, friction force torque (friction coefficient, friction force), test time and other parameters of this machine are controlled by computer, and it can collect test data in real time and draw corresponding test curves, support arbitrary storage, access and printing and output, with accurate and reliable data, without influences of human factors.

II. Main technical specifications:

1. Maximum load 20Kg (directly loaded by the servo motor)

2. Loading accuracy of test force: ±1%;

3. Maximum friction torque: 1N.m;

4. Error of friction coefficient: ±1%;

5. Display accuracy of friction torque: ±0.005N.mm

6. Diameter of pin specimen: 4mm optional;

7. Maximum diameter of disk specimen: 60mm;

8. Control mode: microcomputer automatic control;

9. Power supply: 220V 50Hz 5A;

10. Rotation speed of spindle: 1-2000r/min servo motor stepless speed change;

11. Contact form: Pin-on-disk type; extendible: double-ring type, end face type;

12. Control system of testing machine:

PYsmart-test advanced professional friction and abrasion software, real-time collection of friction force data by computer, and it adopts the high-stability modular integration principle, and it supports one-key setting of test parameters, full-automatic loading, whole-process real-time tracking of curve, random enlargement, editing and storage of curves of any time, automatic optimization of curve, single-point collection; it supports real-time data recording and has the function of power-down save, and it can output shared data and support secondary editing, comparison and processing;

It has the functions of upper limit force protection and lower limit protection, and soft emergency stop protection, time control, rotation speed (cycle) control, friction force torque control and so on.

III. Data output mode, operation and control mode

This machine uses PC computer for control and collection of data, and it is configured with software and hardware with proprietary intellectual property rights; test data and curves can be fully saved in the computer host in TXT, WORD, EXCEL and other forms, and they can be accessed and copied at any time. Meanwhile, this machine is equipped with one ink-jet printer, and data can be printed at any time for scientific research work purpose.

It is operated by PC computer keyboard and mouse, and after the operating software is opened, the human-computer interface is friendly, and parameters can be set randomly as required, and then, test force, temperature, rotation speed and so on can be automatically applied, and it is convenient to operate.

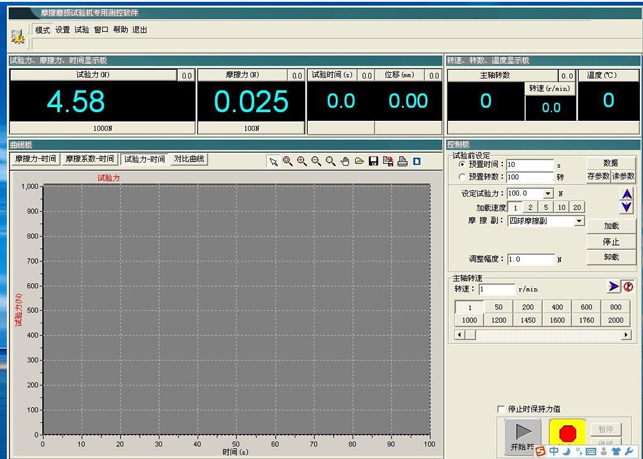

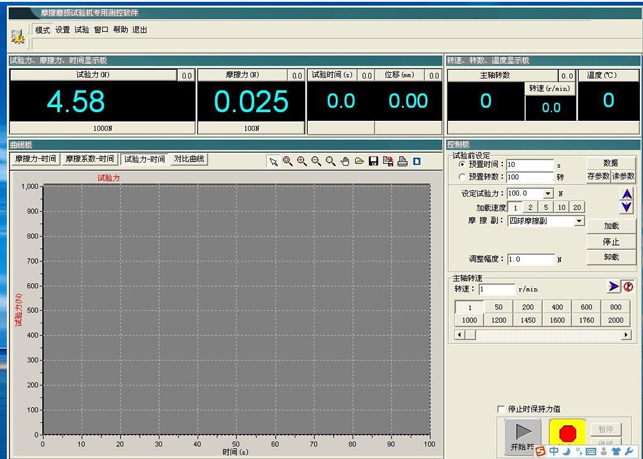

Software system interface

1. Main function interface

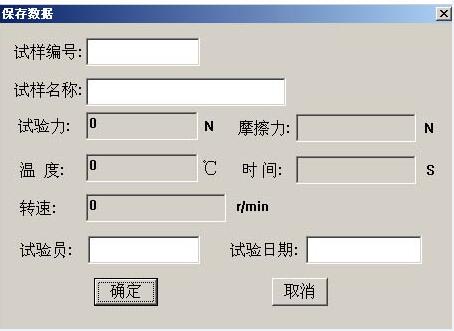

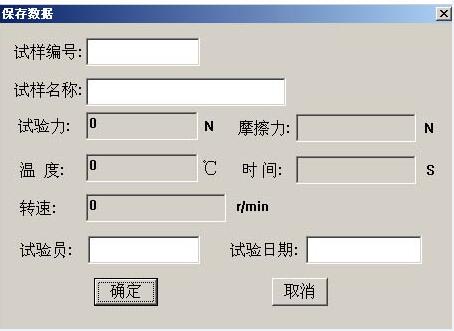

2. Save data interface

This machine uses PC computer for control and collection of data, and it is configured with software and hardware with proprietary intellectual property rights; test data and curves can be fully saved in the computer host in TXT, WORD, EXCEL and other forms, and they can be accessed and copied at any time. Meanwhile, this machine is equipped with one ink-jet printer, and data can be printed at any time for scientific research work purpose.

It is operated by PC computer keyboard and mouse, and after the operating software is opened, the human-computer interface is friendly, and parameters can be set randomly as required, and then, test force, temperature, rotation speed and so on can be automatically applied, and it is convenient to operate.

Software system interface

1. Main function interface

2. Save data interface

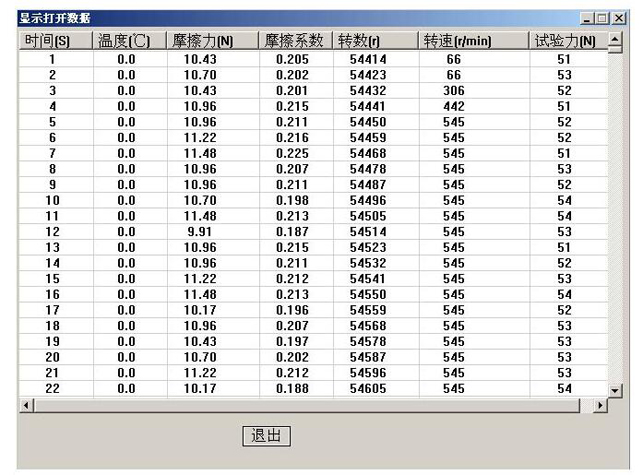

3. Display data interface

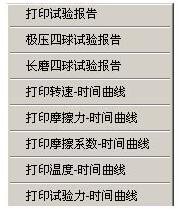

4. Print statements and curves

IV. Measurement of friction coefficient and abrasion loss

According to Coulomb law F=μ.N

Where, F……friction force (Newton)

μ……friction coefficient

N……positive pressure (Newton)

Where, N is the load value upon test, while friction force F multiplied by friction radius of specimen 0.013m or 0.0135m is friction force torque M (Newton. meter) measured by this testing machine, so μ can be calculated according to the following formula:

μ= (pin-on-disk specimen) or μ= (double-ring specimen)

Where, M……(Newton. meter)

N……load (Newton)

The abrasion loss can be measured with the weighing method and the length measuring method.

上一篇:MMH-1 Multifunction Ring Block Friction and Wear

下一篇:没有了