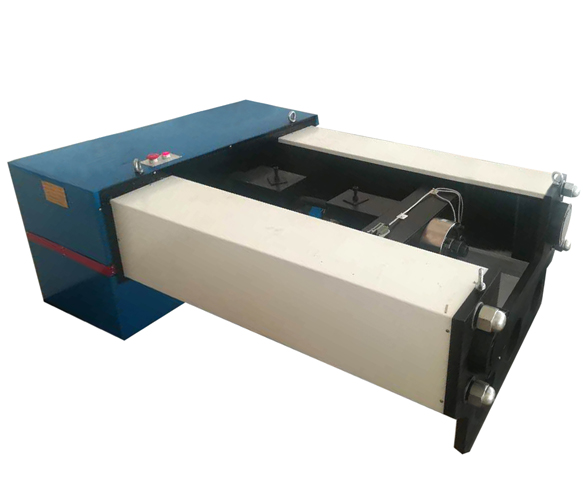

WDL-300C microcomputer controlled vehicle-mounted horizontal

Purposes of product

This product is mainly used for the tensile test of coal mine link chain and tension shear test of connecting bolt, and it applies to the on-site test of coal mine. This machine adopts horizontal lightweight design, and the rack adopts six-column structure, and it can be mounted on light buses (Iveco) or light truck (Shidai Light Truck), and after arriving at the site, it can be just connected with 220V power supply. The loading system adopts AC servo motor, and the tensile test force is applied by the beam through the driving ballscrew of reducing mechanism, and it adopts computer closed-loop control over servo motor, automatic control of test process, force measurement by load sensor, real-time display of test force and test curve on computer screen, and automatic processing of test data according to the test method. The control unit is composed of computer and servo control system, and it has stress, strain and displacement control modes, which can be switched smoothly. It can realize arbitrary access of test data, re-analysis of data and curves, local enlargement and data re-editing, programmability of specimen, environment and test conditions, and it can automatically determine various mechanical performance indexes of materials and print complete test reports and curves. This machine consists of rack, fixed base, moving beam, sensor, servo motor and control system and software; it adopts the servo motor made in Taiwan as power element to apply the tensile load of 300kN; the whole process of test is set and controlled by computer, being easy and convenient to use; the main part of machine, i.e. force measuring sensor, is a product of American TRANSCELL brand (with high precision and good stability), and the ballscrew is product of a Taiwan brand, while other accessories are products of domestically famous brands, with long-term stability and reliability in use.

Performance features

1. Microcomputer control, menu prompt on the software interface, easy operation;

2. Function of report self-editing by users. The data can be conveniently imported into Excel forms, making it convenient for users to carry out post processing;

3. The test process and measurement, display and analysis are completed by microcomputer;

4. Automatic shift: Shifting to the proper measurement range automatically according to the size of load, guaranteeing the accuracy of measured data;

5. Automatic speed change: The beam speed can automatically change according to the preset program during the test process, and it can also be manually shifted;

6. Curve selection: You can select force-time/force-displacement/force-deformation curves for display and printing;

7. Various protection measures. For example, various electrical protection of power links, overload of software part, over-displacement protection, and mechanical compulsory safety limit protection;

8. The host is of framework horizontal structure, and the rigidity of the whole machine is high; the power adopts the servo motor to drive the ballscrew to rotate and drive the beam to move, with stable loading, high control accuracy, low noise, long life of testing machine and good long-term stability and energy conservation;

9. Arc tooth synchronous deceleration system, being advantaged by high efficiency, long life, low noise and maintenance-free.

Standards

The testing machine meets the requirements of such national standards as GB/T16491-2008, JJG 475-2008, GB/T16825.1-2008 and GB/T 228.1-2010. It applies to the following standards: MT244.1-2005 Car Coupler of Decauville for Mine – Connecting Chain, MT244.2-2005 Car Coupler of Decauville for Mine – Connecting Bolt, AQ1112-2014 Testing Specification of In-service Connecting Chain of Decauville Car for Coal Mine, as well as AQ1113-2014 Testing Specification of In-service Connecting Bolt of Decauville Car for Coal Mine.

Main technical parameters

1. Accuracy class: Class 1;

2. Maximum load: 300kN;

3. Effective force measurement range: 6~300kN(2%~100% of the maximum load)

4. Force measurement accuracy: Within ±1% the indication;

5. Resolution of test force indication: 1/500000 of the maximum test force

6. Deformation measurement error: Within ±1% of the indication

7. Deformation resolution: 1/500000 of the maximum deformation

8. Control range of displacement speed: 0.001mm/min ~ 250mm/min stepless speed regulating

9. Error of displacement indication: Within ±1% of the indication

10. Displacement resolution: 0.05μm

Other parameters

1. Effective test width: 550mm;

2. Effective tensile space: 500mm;

3. Safety device of testing bench: Electronic limit protection;

4. Return of testing bench: In the manual mode, the testing bench will return to the initial position upon test at the highest speed; in the automatic mode, the testing bench will automatically return after tests finish;

5. Overload protection: Automatic protection when exceeding 10% of the maximum load;

6. Earth leakage protection: Automatic earth leakage protection.

7. Motor: AC220V±10% 1KW;

8. Dimension of motor: Approximately 1800mm×1040mm×685mm;

9. Weight of motor: Approximately 700kg.

10. Specimen: Standard three-link and bolt for coal mine.

上一篇:LAW Series Horizontal Tension Testing Machine

下一篇:没有了